In the ever-evolving world of 3D printing, dual extruder printers have emerged as a powerful tool for both hobbyists and professionals. These machines, which feature two separate nozzles for filament extrusion, open up a wide array of creative and technical possibilities. However, along with their impressive capabilities come certain drawbacks that potential users should be fully aware of. This article outlines the key pros and cons of dual extruder 3D printers to help you make an informed decision.

Advantages of Dual Extruder 3D Printers

1. Multi-Material Printing

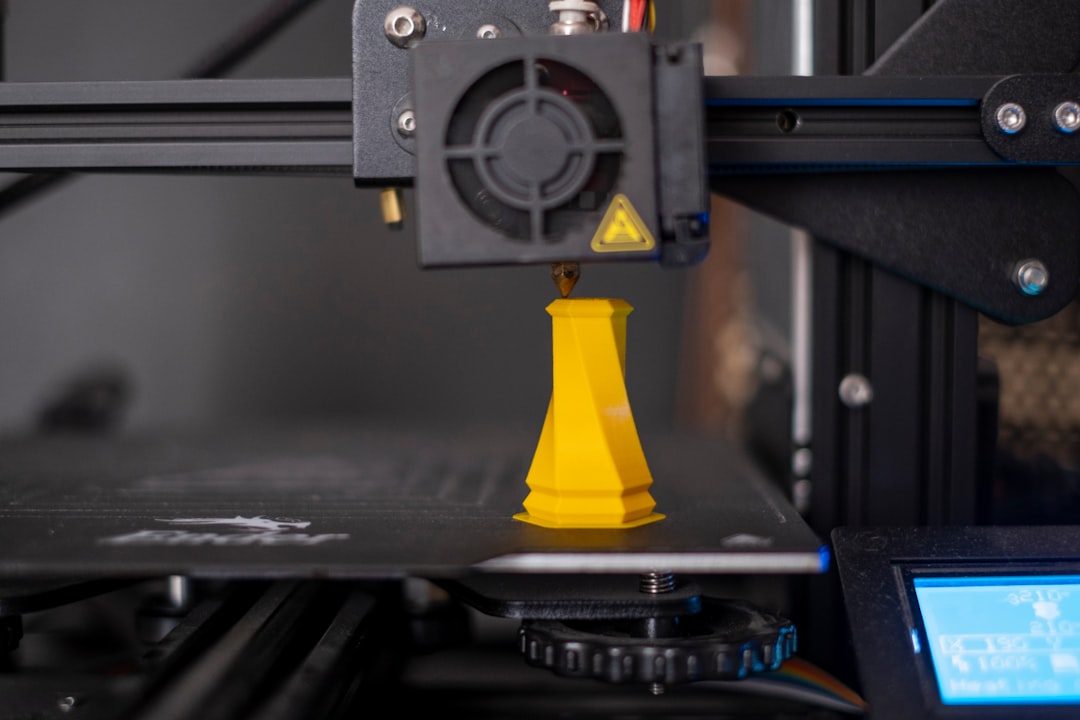

One of the most significant benefits of dual extruders is the ability to print with two different materials simultaneously. This expands functionality in several ways:

- Soluble Supports: Print structural components with one material and support structures with a water-soluble filament like PVA, making post-processing easier and more precise.

- Flexible and Rigid Combinations: Combine flexible filaments like TPU with rigid ones like PLA for functional designs such as wearable devices or complex enclosures.

2. Multi-Color Capabilities

Dual extrusion also allows for printing objects with two distinct colors without the need to stop and manually change filaments. This capability is especially beneficial for aesthetic models, signage, or custom branding projects where color variation enhances the visual appeal and detail.

3. Enhanced Print Quality and Complexity

More complex geometries become feasible with dual extruders. For instance, printing intricate overhangs or internal channels is made much easier with breakaway or dissolvable support materials. As a result, dual extruder printers are frequently used in professional environments for prototyping and even in some low-scale manufacturing scenarios.

4. Time-Saving

While the setup might take a bit more time upfront, dual extrusion can ultimately save time during multi-material or color prints since it avoids manual filament swapping and repeat setups.

Disadvantages of Dual Extruder 3D Printers

1. Increased Cost and Maintenance

An obvious downside is the significant price increase compared to single-extruder models. Not only are dual-extruder printers more expensive to purchase, but they also come with additional maintenance needs:

- Dual nozzles require regular calibration and cleaning to prevent clogging.

- Hardware issues are more likely due to the added complexity.

Moreover, spare parts for dual-extruder systems can be more expensive and less readily available than their single-extruder counterparts.

2. Calibration Challenges

Aligning two nozzles perfectly is no small feat. Poor calibration can lead to failed prints, nozzle collisions, and inconsistent layering. While newer models may come with automatic calibration features, many users still struggle with setup, especially those who are new to 3D printing.

3. Slower Printing Speeds

Contrary to what one might expect, printing with dual extruders often takes longer. Tool-switching times add up during complex prints, and the need for cooling processes between switches may further slow progress. In some cases, users report increased print times of up to 30% compared to single-nozzle workflows.

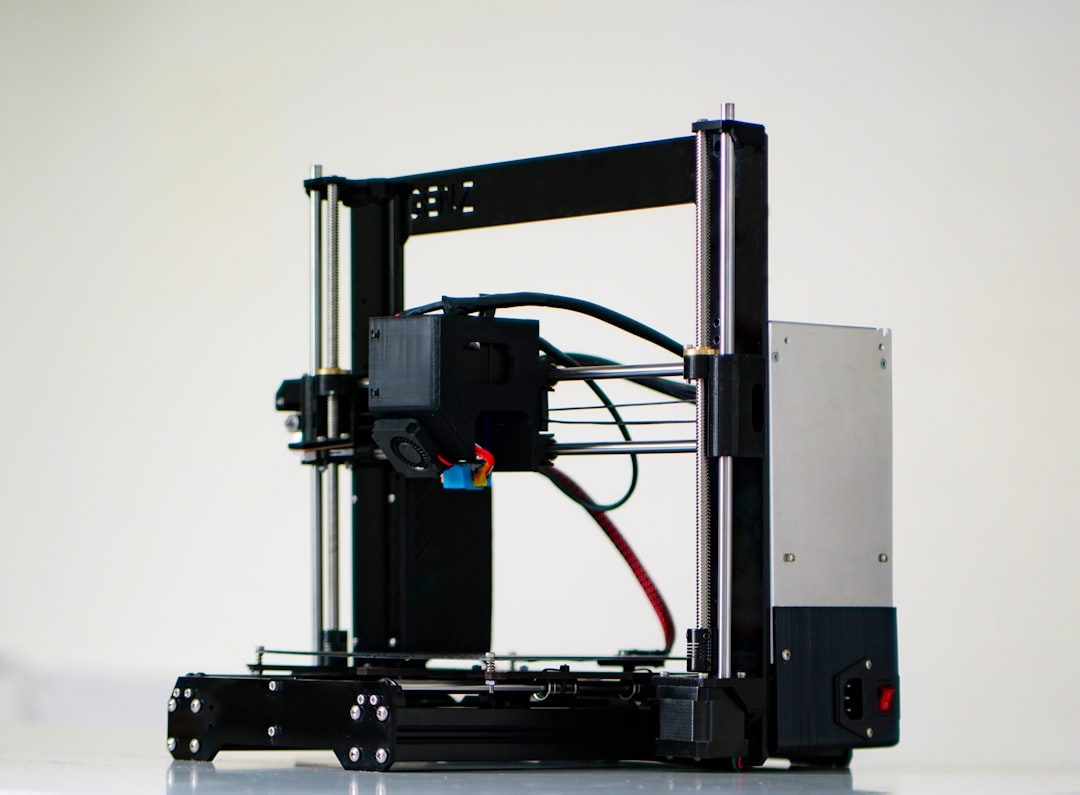

4. Larger Footprint

Dual extruder 3D printers are generally larger and heavier. This added bulk can be a disadvantage for users working in limited spaces. Additionally, the increased power consumption and potential noise levels may be problematic for office or home environments.

Is a Dual Extruder Printer Right for You?

In summary, dual extruder 3D printers offer considerable benefits for those seeking flexibility, improved print quality, and more sophisticated projects. However, they also come with a steeper learning curve, added costs, and increased maintenance responsibilities.

If your work requires multi-material output or precision support structures, then the investment in a dual extruder printer is likely justified. On the other hand, if you’re a beginner or tend to print simple models, a high-quality single extruder printer may be more suitable and cost-effective.

Ultimately, understanding your needs and the capabilities of the technology is the key to making the right choice in today’s diverse 3D printing landscape.